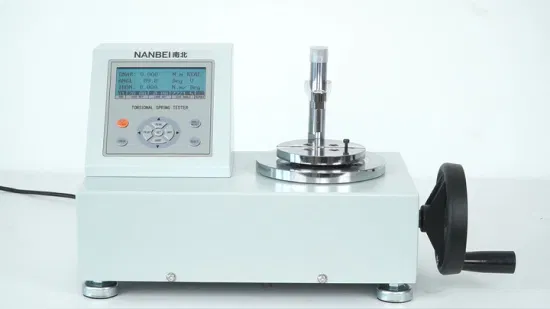

Ndw2000 Digital Display Metal Sheet Material Torque Torsion Testing Machine

Basic Info.

| Model NO. | NDW-1000/2000 |

| Mass Scope of Workpiece | <900kg |

| Type | Torsion Testing Machine |

| Maxcapacity | <1000KN |

| Load Way | Electronic Load |

| Loading Method | Static Load |

| Display | Digital |

| Control | Manual Control |

| Weight | 100-500Kg |

| Power Source | AC220V |

| Oil Cylinder Position | Under |

| Torque Resolution | 1/500000 |

| Clearance Between Grips(mm) | 500 |

| Torque Effective Test Range(F·s) | 0.4%~10 |

| Relative Error of Torque | 0.5% |

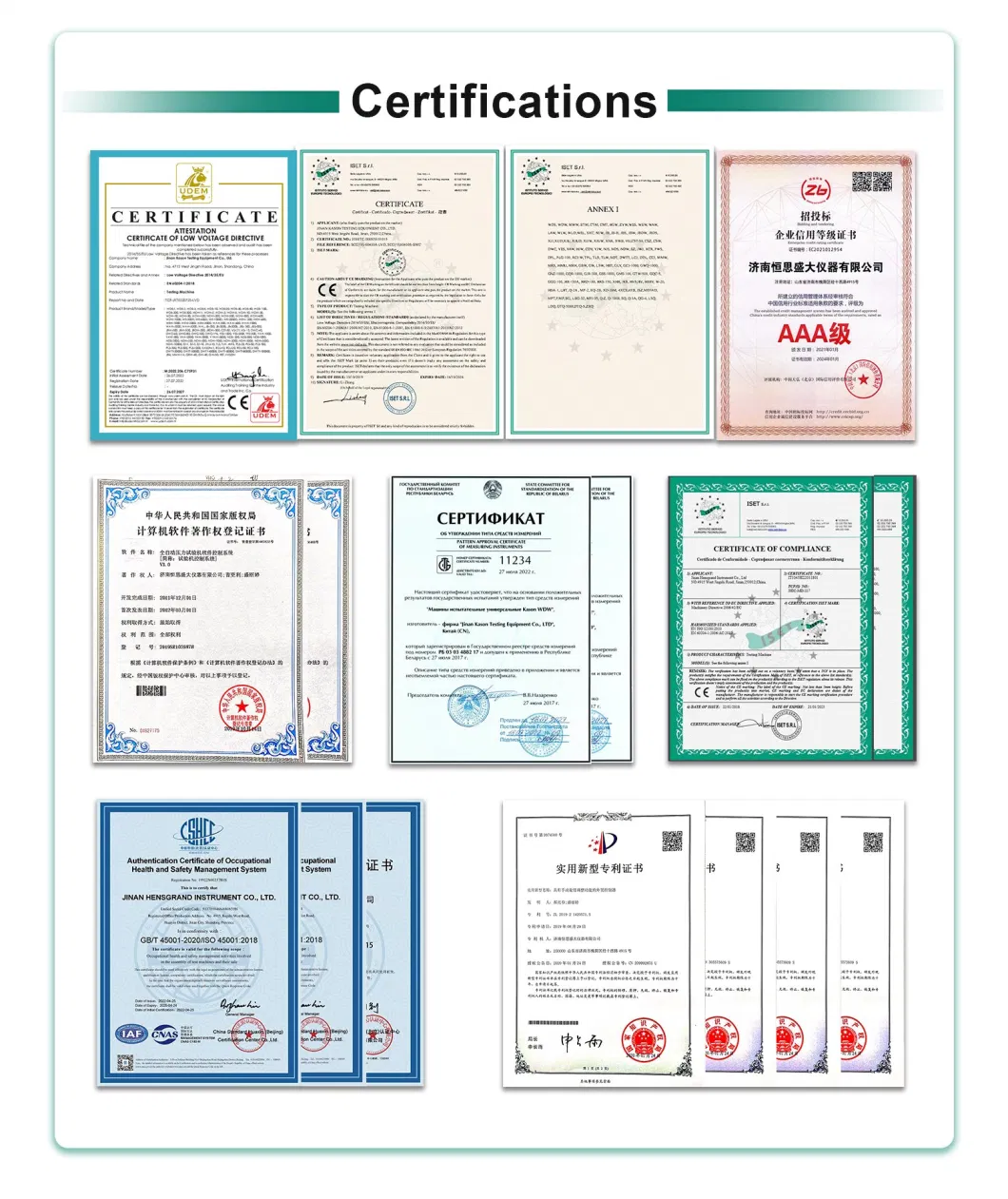

| Certification | CE ISO |

| Maximum Torque | 2000nm |

| Delivery Time | 3 Days After Get Payment |

| Transport Package | Standard Export Packing |

| Specification | 1250x450x1190 |

| Trademark | HST |

| Origin | China |

| HS Code | 9024101000 |

| Production Capacity | 300 Sets Per Month |

Packaging & Delivery

Package Size 261.00cm * 75.00cm * 136.00cm Package Gross Weight 1500.000kgProduct Description

NDW2000 digital display metal sheet material torsion tensile testing machineProduct Description

Application:

Wire torsion testing machine applies to determine the ability of diameter(or feature size) of 0.1-20.0 mm wire for bearing plastic deformation in one way or two way torsion test, display the surface and internal defects of the wire. Provide reliable data for production of wire and wire rod company. Widely used in aerospace, metal material processing, tire manufacturing industries, and institutions of higher learning, scientific research institutions, technical supervision, quality inspection departments and so on.

Standard: Wire torsion testing machine

GB/T2611-2007 General requirements for testing machines

GB/T 239-1999 Metal wire twisting test method

ISO 7800:1984 Metal wire one-way torsion test method

ISO 9649:1990 Metal wire two-way torsion test method

Could add special gips to do the wrap winding testing machine.(optional)

Features:

1) One way torsion :Sample around its own axis in one direction evenly rotate 360 ° as a torsion,

until to the stipulate times or sample breakage.

2) Two way torsion:Sample around its own axis in one direction evenly rotate 360 °

as a torsion, until after to the stipulate times,then rotate same times in opposite direction or sample breakage.

3) Number setting:Automatic stop when reach the presetting torsion number;

4) Rotation speed adjustable:Adopting adjustable- speed motor knob switch,

5) Display mode:Digital real time display

Technical parameter:

Model | EZ-3 | EZ-10 | EZ-20 | EZ-30 |

Working method | Automatic loading | |||

Max Clamp metal wire diameter(mm) | 0.2-3 | 2-10 | 10-20 | 10-30 |

Parallelism degree of mobile guide rail within the total length scope | ≤0.2 | |||

Max distance between two columns | 320 | 520 | 600 | 600 |

Rotation speed adjusting range (r/min) | 0-180 | 0-60 | 15-20 | |

Speed error | <±1% | |||

Minimum reading value of circle | 0.1 | |||

Two chucks comicality | < 0.4 | |||

Jaw hardness ( HRC ) | HRC55-65 | |||

Weight error | ±0.5% | |||

Working Noise (dB) | ≤70 | |||

Power supply | AC220V±10% ,50HZ | |||

warranty :1. 2 years warranty for machine host. English technical to door service2.English manual and Video CD for machine using and maintenance.We offer free training in our factory, welcome to visit and learn more about our machines.3.Free accessories :Software ,manual, book, cd videos, USB control .After-sales service:Training to install (3 options): A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting. B. You can come to our factory for training. We will offer professional guide. Direct and effective face-to-face training.all sorts of tools and testing facility,we will also provide accomadation during training period.

Contact Information