Electronic Servo Universal Torsion Test Machine 1000kn for Rebar/Waw

1. Qiantong main scope of testing machineElectronic universal material testing machine, Horizontal tension testing machi;

Basic Info.

| Model NO. | QT-60100D |

| Loading Method | Dynamic Load |

| Display | PC Computer |

| Control | Computer Control |

| Weight | 3000kg |

| Power Source | AC380V |

| Oil Cylinder Position | Under |

| Warranty Time | 1 Year |

| Customized or Not | Customized |

| Transport Package | Wooden Case |

| Specification | 850*665*2340mm |

| Trademark | SUZHOU QIANTONG |

| Origin | Jiangsu, China |

| HS Code | 9024800000 |

| Production Capacity | 1000 Set/Year |

Product Description

1. Qiantong main scope of testing machineElectronic universal material testing machine, Horizontal tension testing machine, Hydraulic universal testing machine, MFI, Charpy Impact, Izod Impact, HDT-Vicat tester, Hardness tester, Torsion tester, Metallographic series, Oven and so on. (We accept customization.)

2. Product QT-60100D Electro-hydraulic servo universal material testing machine can play electro-hydraulic servo automatic control, automatic measurement, data acquisition, display and processing of the experiment result into an role. With housing under the conditions of the oil cylinder host as the platform, configuration precision pump and electro-hydraulic servo valve, servo controller and PC to realize the multichannel closed loop control can complete test process of automatic control, automatic measurement functions. It has good professional, the characteristics of high reliability, easy upgrade and other features. And with the development of the tester measurement and control technology and test standard changing constantly enrich the consummation

3. Features of control and data processing system

1.Host: It is equipped with cylinder - mounted host frame. The structure greatly reduces the height of host. And it has convenient transportation, installation,stable performance and reliability. The test bed is drive by motor, chain and lead screw, which realizes the adjustment of tension space and the test operation is convenient.

2.Test and control system:combine with electro-hydraulic servo oil source,full digital PC servo controller, electro-hydraulic servo valus, pressure sensor, extensometer for measuring specimen deformation, photoelectric enconder for measuring displacement, PC measurement and control card for testing machine, printer, multi-function test software package, electrical control unit and other parts.

3.Standard electro-hydraulic servo oil source:

1)It is designed, manufactured and manufactured in accordance with standard modular unit with mature technology for load adaptive oil inlet throttle speed regulation system, specially used for electro-hydraulic servo universal testing machine.

2)It is chose by mature technical oil pump - motor, and has reliable quality, stable performance.

3)The load adaptive throttle speed regulating valve developed and produced by ourselves with unique technology, the system pressure is stable, adaptive constant pressure difference flow regulation, no overflow energy consumption, easy to carry out PID closed-loop control.

4)Pipe system: Pipelines, joints and seals are made of groups with stable performance to ensure reliable sealing of hydraulic system and no oil leakage failure.

4.Electrical control cabinet:

1)All the strong current components of the system are concentrated in the strong current control cabinet, which can effectively separate the strong current unit from the weak current unit of measurement and control, so as to ensure the measurement and control system from interference and long-term stable work.

2)Manual operation button is set on the electric control cabinet, including power switch, emergency stop and start and stop of oil source oil pump, etc..

5.Full digital PC servo control system

1)With PC computer as the main part, the system is fully digital PID regulation, equipped with PC clamping servo amplifier, measurement and control software and data acquisition and processing software, which can realize the closed-loop control of test force, sample deformation, piston displacement and smooth switching of control mode.

2)The system consists of three signal conditioning units (test force unit, cylinder piston displacement unit, specimen deformation unit), control signal generator unit, servo valve drive unit, servo oil source control unit, necessary I/O interface, software system and so on.

3)The closed-loop control loop of the system: the measurement sensor (pressure sensor, displacement sensor, deformation extensometer), servo valve, controller (each signal conditioning unit) and servo amplifier together form several closed-loop control loops to realize the closed-loop control functions of the testing force of the testing machine, the displacement of the cylinder piston, and the deformation of the sample. It has many control modes, such as equal rate test force, equal rate oil cylinder displacement, equal rate strain, etc., and can realize smooth switching of control mode, so that the system has greater flexibility.

6.PC - board servo amplifier for tester

1)It is a pluggable PC card board, which is specially designed for testing machine with advanced computer bus control technology, including program-controlled analog amplifier, A/D conversion, digital data acquisition channel, digital data I/O, etc

2)The special measurement and control card and PC unit into a single card measurement and control system, can be directly connected with the sensor, measurement and control and data acquisition, and make the complex measurement and control and data acquisition system become simple and reliable

3)Using computer bus technology, directly into the computer expansion slot, full digital circuit, zero adjustment, gain adjustment and so on are realized by software. It is the latest product unit of testing and control technology development of testing machine

4)Gain programmable cascade amplifier can get different gain magnification

5)The bridge power supply of the sensor shares the same voltage with the reference voltage of A/D chip, and the whole measurement system attenuates year-on-year, realizing the hardware compensation technology of the bridge power supply

6)The multi-bit A/D conversion satisfies the sensitivity and resolution requirements of the system, and avoids the software frequency doubling method reducing the characteristics of the system

7.Multifunctional test software package

1)Operating system Windows98/XP/2000 platform, Chinese operation interface

2)The computer screen displays the test force, cylinder displacement, loading rate and deformation test data, and draws various test curves such as time-test force/deformation and deformation-test force. Automatic data processing, data processing methods meet the requirements of gb228-2002 standard, such as upper and lower yield points, maximum force points, all kinds of specified non-proportional stress points, all kinds of specified full elongation stress points, etc. At the same time meet the pressure test requirements of the testing machine

3)Software can simultaneously provides data analysis function to satisfy the data processing of test personnel for test analysis and special test

4)It has strong graphics operation functions, such as dynamic test curve and digital display function, graphics amplification and interception function, cursor following and display function, etc

5)VXDs high-speed data acquisition technology is adopted to realize multi-channel (up to 16 channels) high-speed data acquisition

6)The system has a complete file operation function for the storage of test curve and test data. Meanwhile, experimental data can be stored in ASCII code form, so as to facilitate users to conduct secondary data processing

7)With single test report output and batch test report output printing function

8.Control system with overload, oversetting, power failure, piston reach the limit position and other protection functions

9.Hydraulic clamping oil source: independent low noise hydraulic clamping oil source, control the clamping and loosening of the chuck.

4. Specifications

| Type | Unit | QT-6030D | QT-6060D | QT-60100D |

| Load capacity | KN | 300 | 600 | 100 |

| Tester level | 1 | 1 | 1 | |

| Precision level | % | 1 | 1 | 1 |

| Measurement range | 2%-100%FS | 2%-100%FS | 2%-100%FS | |

| Maximum strength space | mm | 520 | 520 | 620 |

| Maximum compression space | mm | 420 | 420 | 520 |

| Distance between column | mm | 460 | 460 | 510 |

| Sensors | oil pressure sensor, photoelectric sensor | oil pressure sensor, photoelectric sensor, extensometer | oil pressure sensor, photoelectric sensor, extensometer | |

| Control mode | electro-hydraulic servo closed-loop control, control mode can be switched smoothly | |||

| Maximum spacing of curved support | mm | 400 | 400 | 500 |

| Host size | mm | 730*570*1845 | 730×570×1900 | 850×665×2340 |

| Control cabinet size | mm | 1010*650*870 | 1010*650*870 | 1010*650*870 |

| Console weight | kg | 2000 | 2000 | 3000 |

| Oil pump motor power | KW | 2.2 | 2.2 | 2.2 |

| Beam moves motor power | KW | 0.37 | 0.37 | 0.55 |

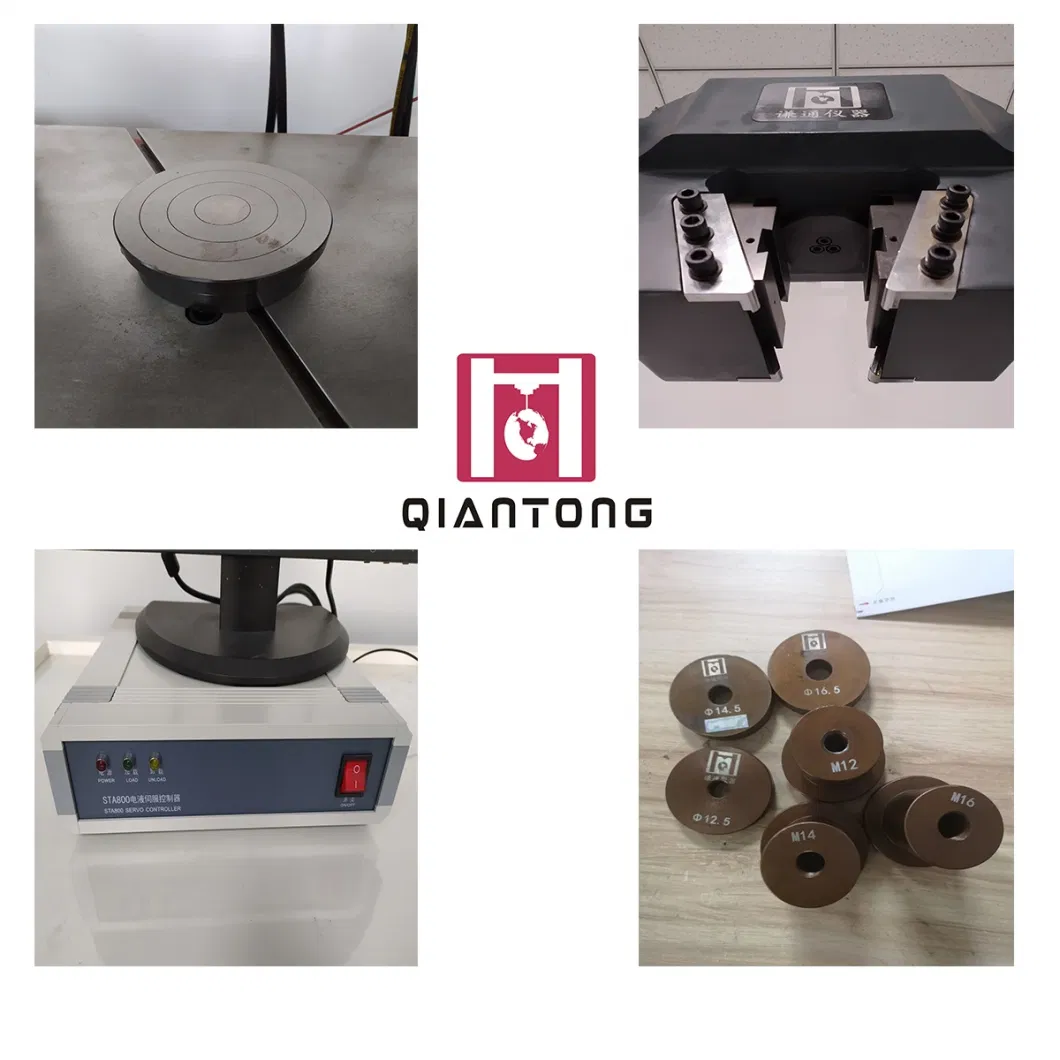

5. Configuration

| NO. | Name | Brand | Unit |

| 1 | Host tester | Suzhou Qiantong | 1 set |

| 2 | Oil cylinder | Suzhou Qiantong | 1 set |

| 3 | Electrical control box | Suzhou Qiantong | 1 set |

| 4 | Electro-hydraulic servo full digital PC controller | Suzhou Qiantong | 1 set |

| 5 | Full digital servo control software | Suzhou Qiantong | 1 set |

| 6 | Controller electrical automation control component | Zhejiang Chint | 1 set |

| 7 | Computer | Lenvov | 1 set |

| 8 | Printer | HP | 1 set |

| 9 | Electro-hydraulic proportional servo valve | Argo-toss | 1 set |

| 10 | Oil pump | Marzocchi | 1 set |

| 11 | Motor | Taiwan S.Y. | 1 set |

| 12 | Hydraulic control valve | Rexroth | 1 set |

| 13 | solenoid valve | Yuken | 1 set |

| 14 | Sensor | Zhenhai | |

| 15 | Fixture | Suzhou Qiantong | 1 set |

| 16 | quality guarantee | Suzhou Qiantong | 1piece |

| 17 | Operating manual | Suzhou Qiantong | 1piece |

| 18 | Factory test report | Suzhou Qiantong | 1piece |

Installation photoes

Exibition photoes

About certifications

FAQ

Q:Are you a trade company or factory?

A:Our company is a factory and directly sales.

Q:Can your company accept customization?

A:Yes. Our machines can be customized by client.

Q:How to guarantee your after-sales service?

A:Our philosophy is one year warranty and lifetime service. After the warranty period is exceeded, if there is any problem, we will provide support for you in time. (only charge travel expense and parts cost at most.)

Q:What is the language about software?

A:It can switch between Chinese and English.

Q:May the customer not use your company's computer?

A:Sure. But please tell us what type your computer is. We need to confirm your computer can install the software. And we can subtract the price of computer from offer.

Q:Can the machine be upgrade?

A:Yes, it can.

Q:Can the machine install a protective door?How much?

A:Yes, we can. About 368$(standard model with one protective door).

Attention please:

Due to the special condition, we holds the preferential activities, the price of all the machines is negotiable. If you are interested in, please contact Wechat/Skype.

You may also like

Send inquiry

Send now